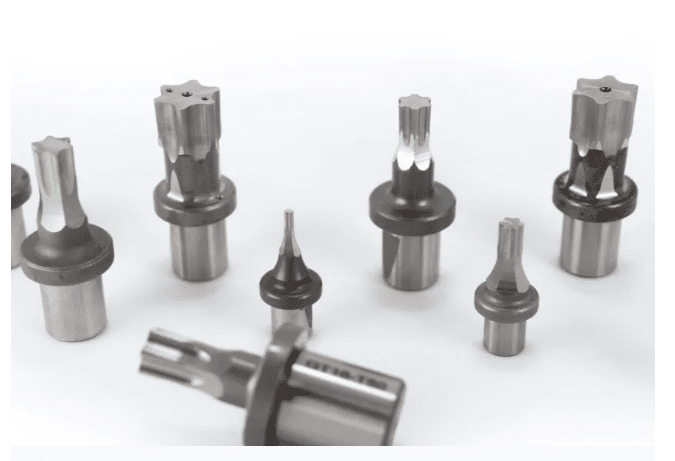

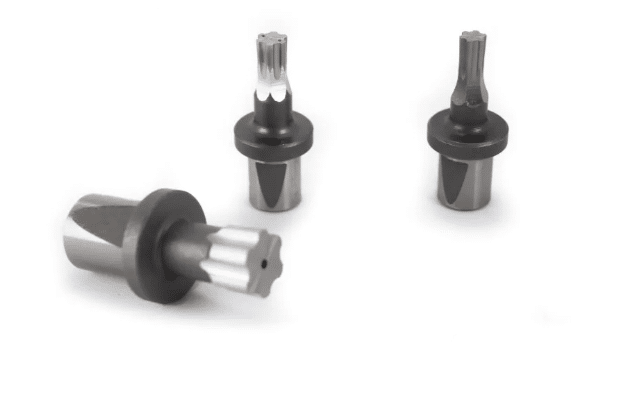

BROACHES FOR INTERNAL HOLES

The BROACH for polygonal holes is a specially shaped tool that is fixed to the spindle of the broaching head on one end, while the other end bears the shape of the hole to be obtained. These broaches are made in two different kind of steels:

– HSS steel. This steel has a good tesistance to wear and tear and a high capacity to absorb the vibrations of the broaching machining

– SINTERED steel. This steel has a high hardness and an excellent resistance to compression, even at high temperatures. It is used for heavy machinings when hard materials are involved (i.e. stainless steels, titanium) BRIGHETTI MECCANICA S.r.l. produces seven kinds of broaches with differenct shanks fitting perfectly the broach seat: G8, G12, G12A, G16, G16L and G25. Beside standard items mentioned in the General Catalogue, BRIGHETTI MECCANICA SRL can produce broaches with special profile and sizes, following Customer’s specification.

Standard and refrigerated broaches for polygonal quarries

METRIC MEASURES

for “BR” and “BRC” series BROACHING HEADS.

Standard and refrigerated broaches for polygonal holes – inch sizes

INCHES MEASURES

for “BR” and “BRC” series BROACHING HEADS.

Standard and refrigerated broaches for Torx® wrenches.

INCHES MEASUREMENTS

for BROACHING series “BR” and “BRC” series