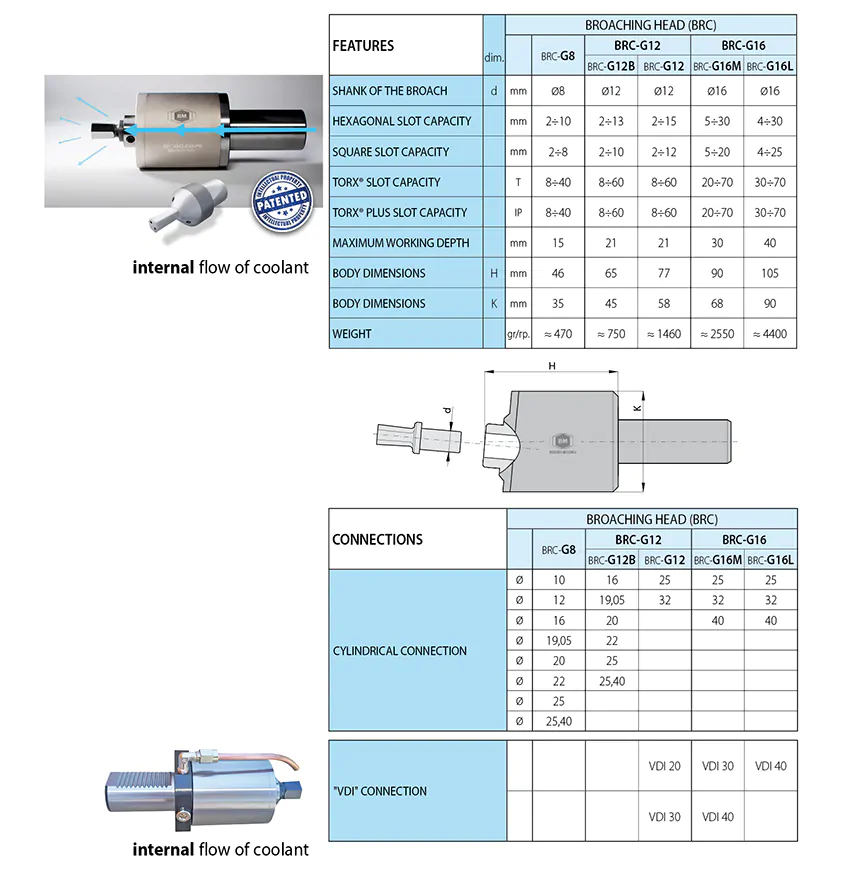

BROACHING HEADS WITH INTERNAL FLOW OF COOLANT

BRC BROACHING SYSTEM:

EVOLUTION BORN FROM INSIDE

Broaching with internal passage of coolant

The new Broaching Brighetti Mechanics BRC has been developed with the same operating characteristics as the similar Brighetti Meccanica BM Broacher, except that modifications have been made internally that allow coolant liquids and/or compressed air to be conveyed from the rear of the attachment tang to the extreme tip of the broach.

The advantages of using the Brighetti Meccanica BRC broaching:

- the sharp edge of the broach is preserved longer

- the inner quarry has a better surface gloss

- advisable for all types of materials, but specifically for: titanium, stainless steel, materials with high magnesium content, in general particularly tough materials in which the chip has difficulty detaching from the walls and broach, such as cast iron, bronze, some aluminum alloys, and plastics

The Broaching is a tool for rapid execution of regular-section polygonal slots

(square, hexagonal, TORX®, toothed, slotted, etc.) in blind or through holes.

In addition, with the help of the adapter, external profiles with a regular cross-section can be made on the same Broaching.

The Broaching can be applied on most rotary motion machine tools, both traditional (lathe, drill, milling machine) and numerically controlled, so it can work both vertically and horizontally.