INSERTS (MM) REV

The broaching and slotting inserts are made with sintered steel alloy with 13% cobalt.

After heat treatment, this material reaches a hardness of 72 HRC all the while preserving high toughness and, therefore, strong resistance to impact.

When all sides have been sharpened, the insert is coated with TIN to achieve greater wear resistance. The protruding shape of the inserts makes it possible to re-sharpen them numerous times.

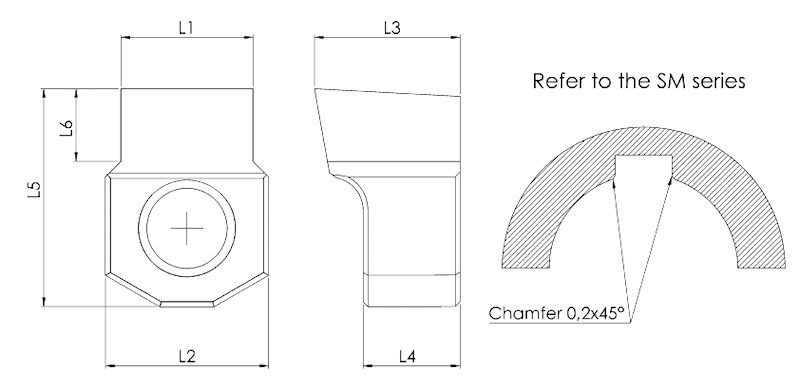

The inserts, identified by their code ending with “SM”, execute 0.2×45° chamfering on the intersection point between the hole and the walls of the broached slot, leaving the hole clear of any burr. This type of chamfering can only be carried out on UNI keyway seatings.

We also manufacture special inserts on customer demand.

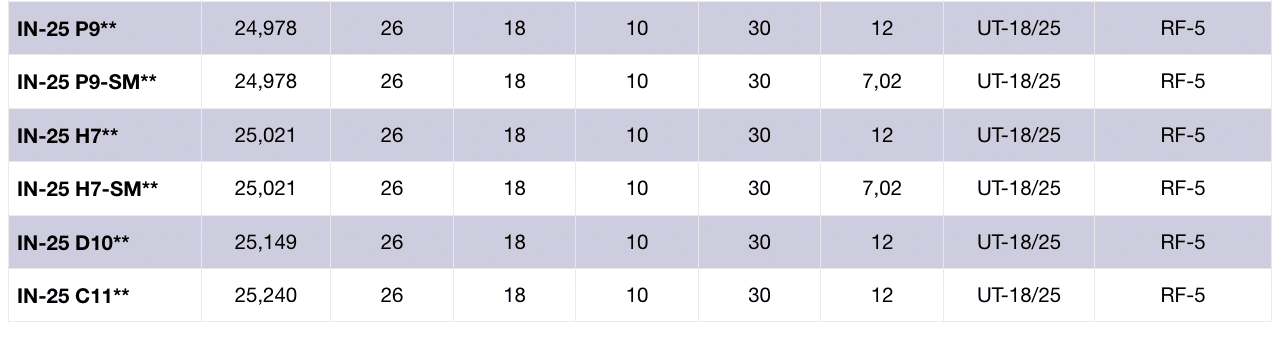

** For these insert sizes, we recommend machining in two steps: roughing and finishing.