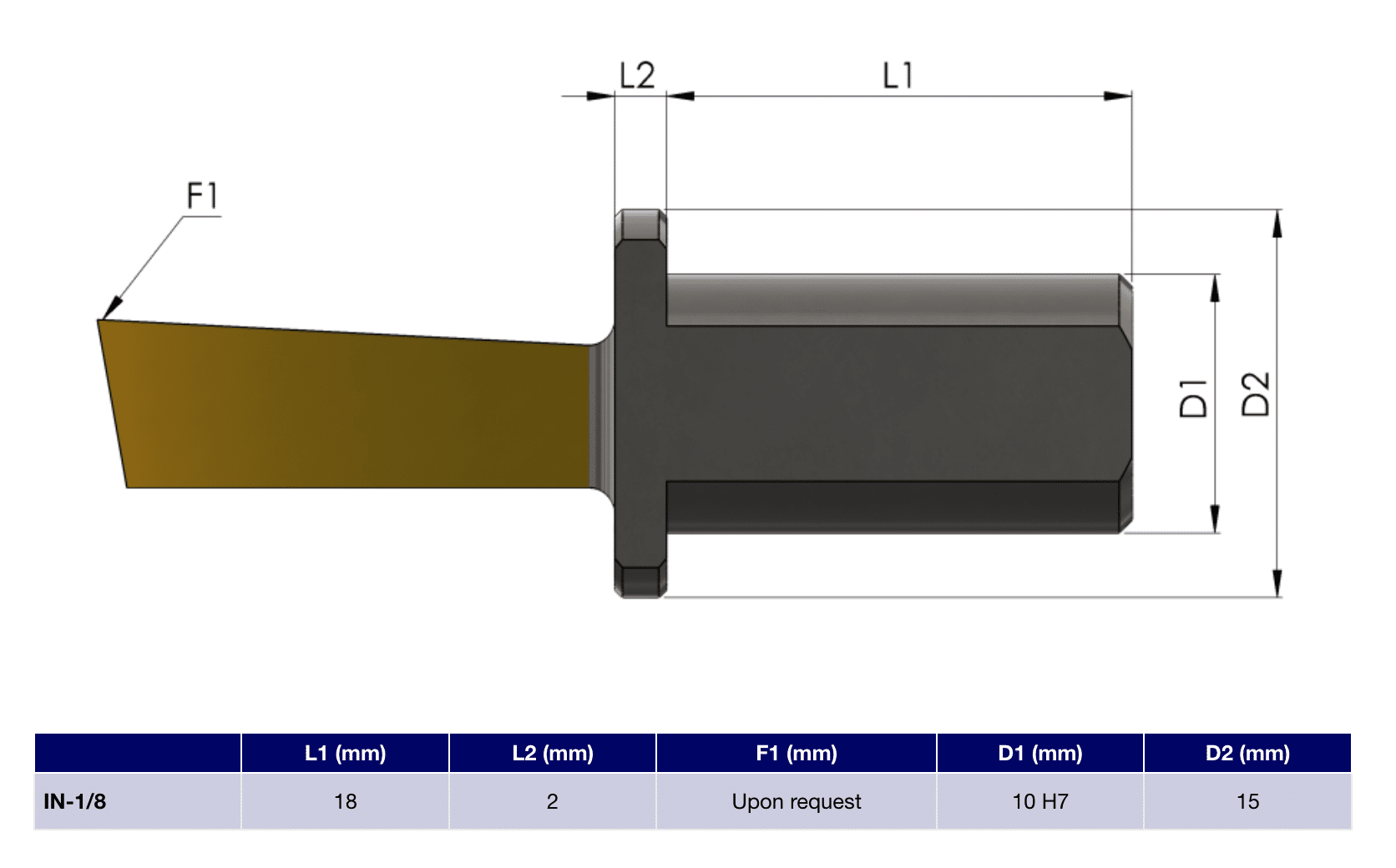

INTEGRAL INSERT REV

Integral inserts in the MINITOOL line feature a flat side on the collar, with a diameter of 15 mm, allowing the operator to check the correct position of the insert in very restricted amounts of time, through the use of common comparators or gauges.

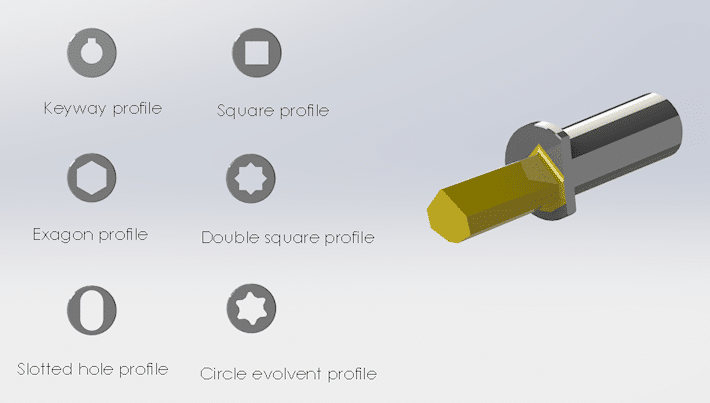

They can be manufactured in two possible alloys: sintered steel or, alternatively, high toughness widia.

The service life of the inserts is very long and they can be re-sharpened many times before having to replace them.

The type of sharpening and coating are assessed based on the material that needs to be machined.

Integral inserts can fit UT-1/8-25 insert-carriers or, alternatively, UT-1/8-32.

The insert-carriers can, in turn, be internally fitted into REV eccentric bushings, the same way as classic line tools and, therefore, can correct any machining alignment errors on CNC lathes that are not equipped with a Y axis.

The service life of the inserts is very long and they can be re-sharpened many times before having to replace them.

The type of sharpening and coating are assessed based on the material that needs to be machined.

Integral inserts can fit UT-1/8-25 insert-carriers or, alternatively, UT-1/8-32.

The insert-carriers can, in turn, be internally fitted into REV eccentric bushings, the same way as classic line tools and, therefore, can correct any machining alignment errors on CNC lathes that are not equipped with a Y axis.