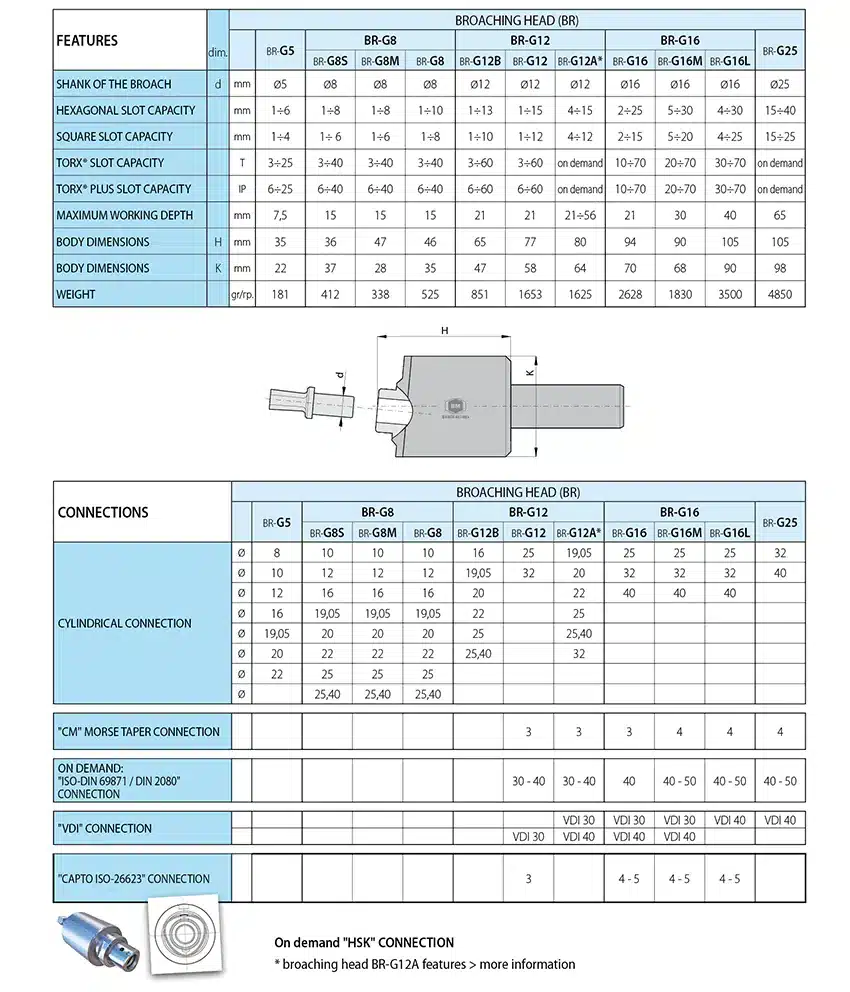

STANDARD FIXED BROACHING HEADS

The spindle that carries the broach is mounted inside the body at a certain angle and, when put into rotation by the machine tool, gives the broach itself a rotary and pendulum motion.

( see Fig.1 )

The combined action of rotation, feed provided by the machine and pendulum motion allow the broach to gently penetrate the workpiece, which has previously been pre-punched, thus creating the desired profile.

Standard “BR” series broaching heads – Specifications and dimensions

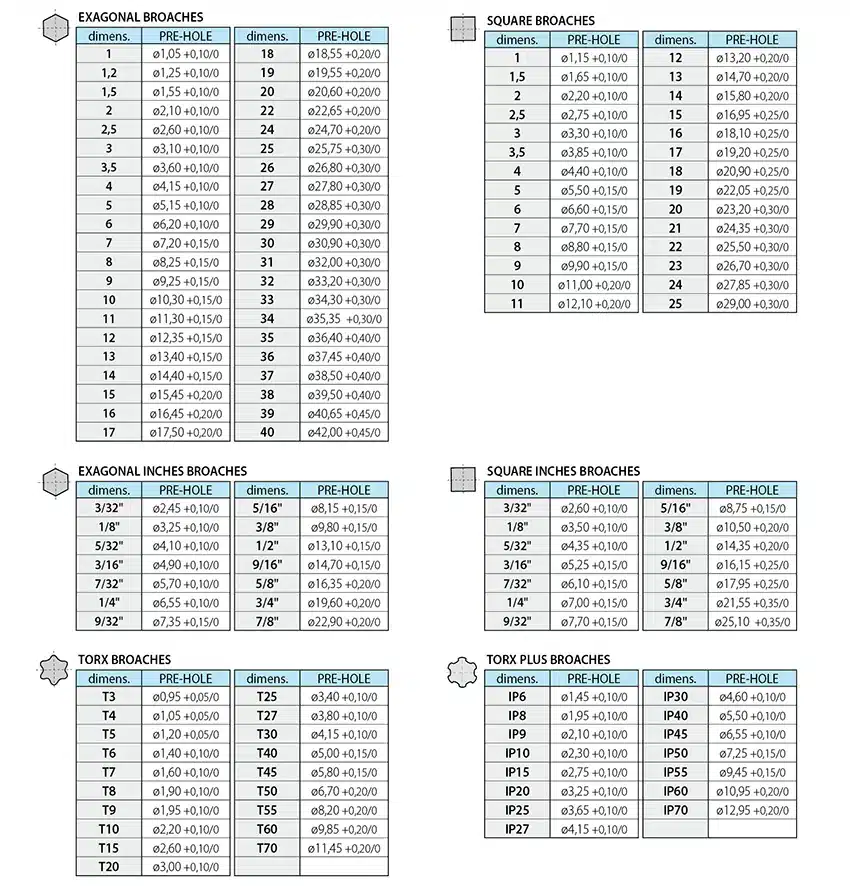

PRE-HOLE BROACHING: EXAGONAL, SQUARE, TORX® AND TORX® PLUS.

Before the broaching procedure it is essential to create a chamfer on the pre-hole. The depth of the pre-hole is increased by: 20% -40% compared to the profile to be obtained; the best solution, however, it’s to get a chip discharge groove, at the end of the profile, to facilitate the chip evacuation.