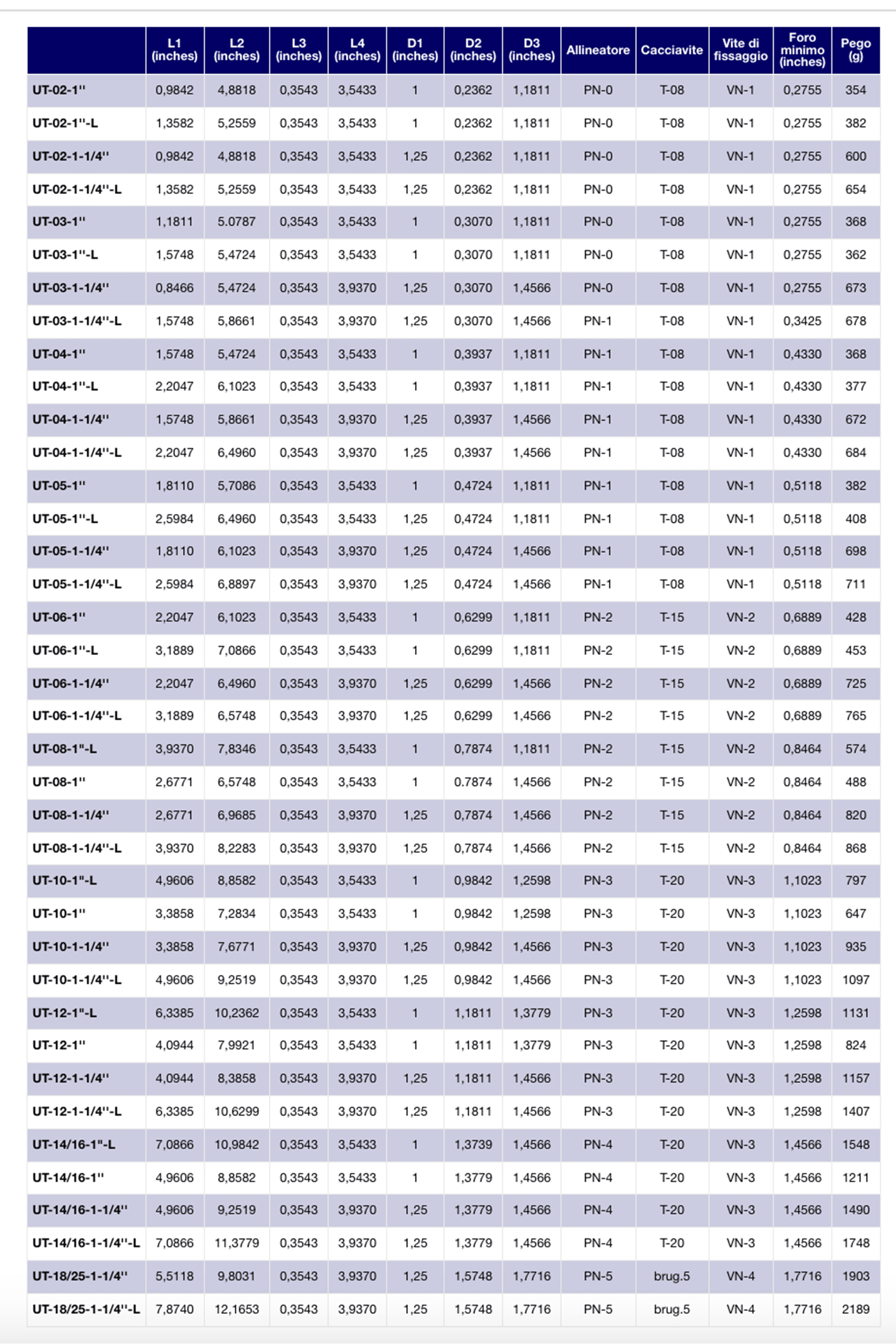

TOOLS FOR INTERNAL MACHINING (INCHES) REV

REV internal tools are made of tempered and tempered tool steel.

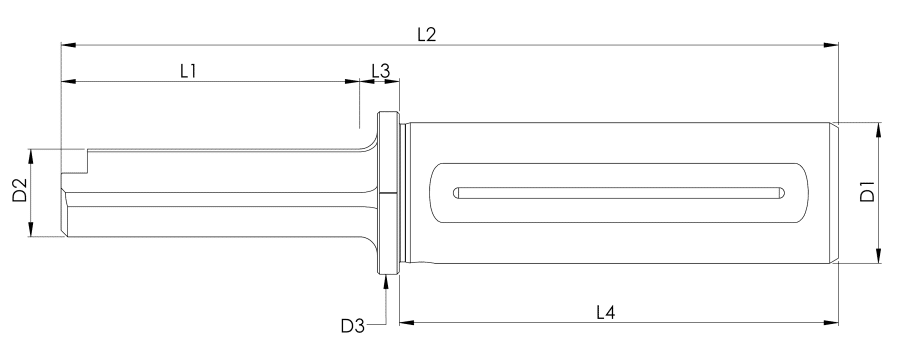

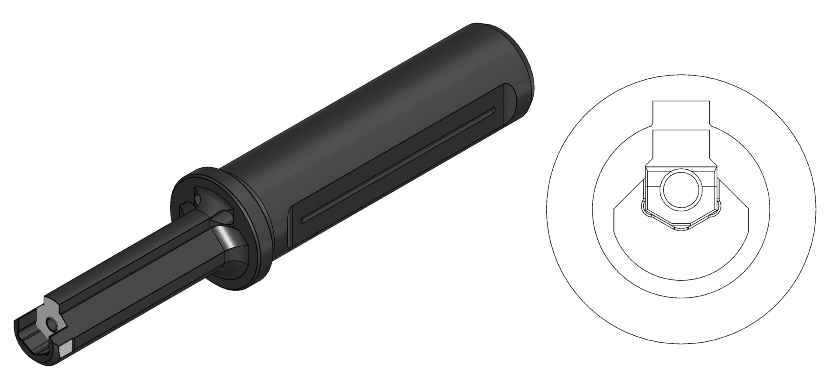

The part where the insert is housed is hardened to 58/60 HRC, in order to make it very resistant to compression and to guarantee a long life to the tool. The majority of REV internal tools (indicated in the table) have 3.5 mm holes for the forced supply of coolant which, in addition to allowing lubrication and cooling of the insert, are used to extract the chip produced from the blind hole from broaching or slotting. Internal tools are available in two gripping diameters (25 and 32 diameters). Two lines of tools are produced for each gripping diameter: a standard one and a long one (indicated with the suffix “L” in the code. The REV Broaching Tool differs from similar tools currently on the market due to the presence of a patented eccentric bushing which eliminates completely symmetry errors.This bushing was created to allow all lathes that do not have the y axis to be able to carry out machining perfectly aligned with the piece.

* 4 mm holes are foreseen for the forced supply of coolant.