TOOLS FOR INTERNAL MACHINING (MM) REV

REV internal tools are made in hardened and tempered steel for tools.

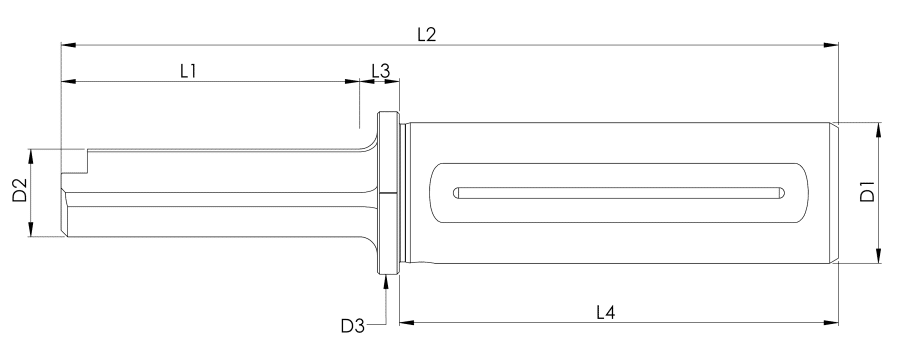

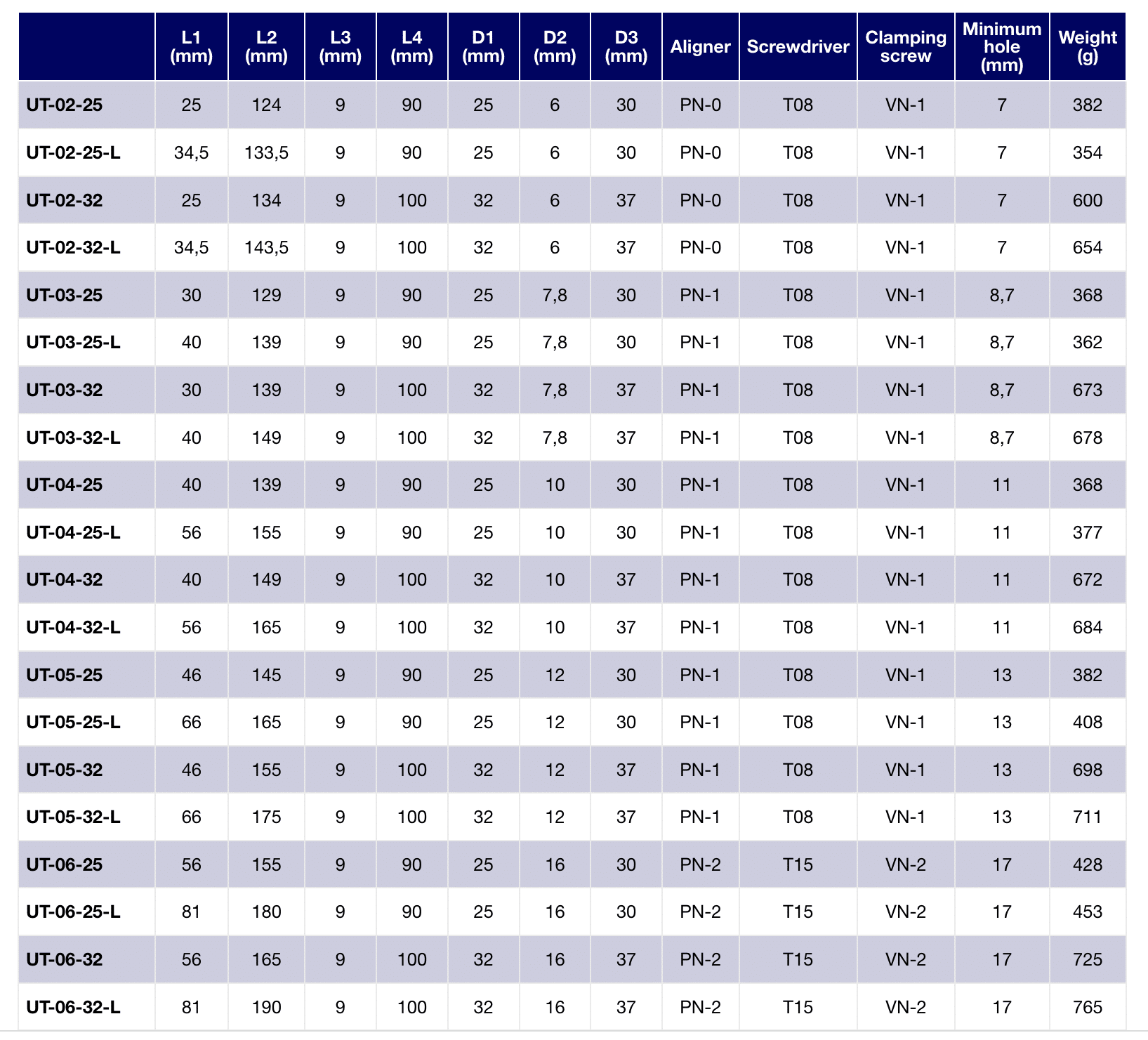

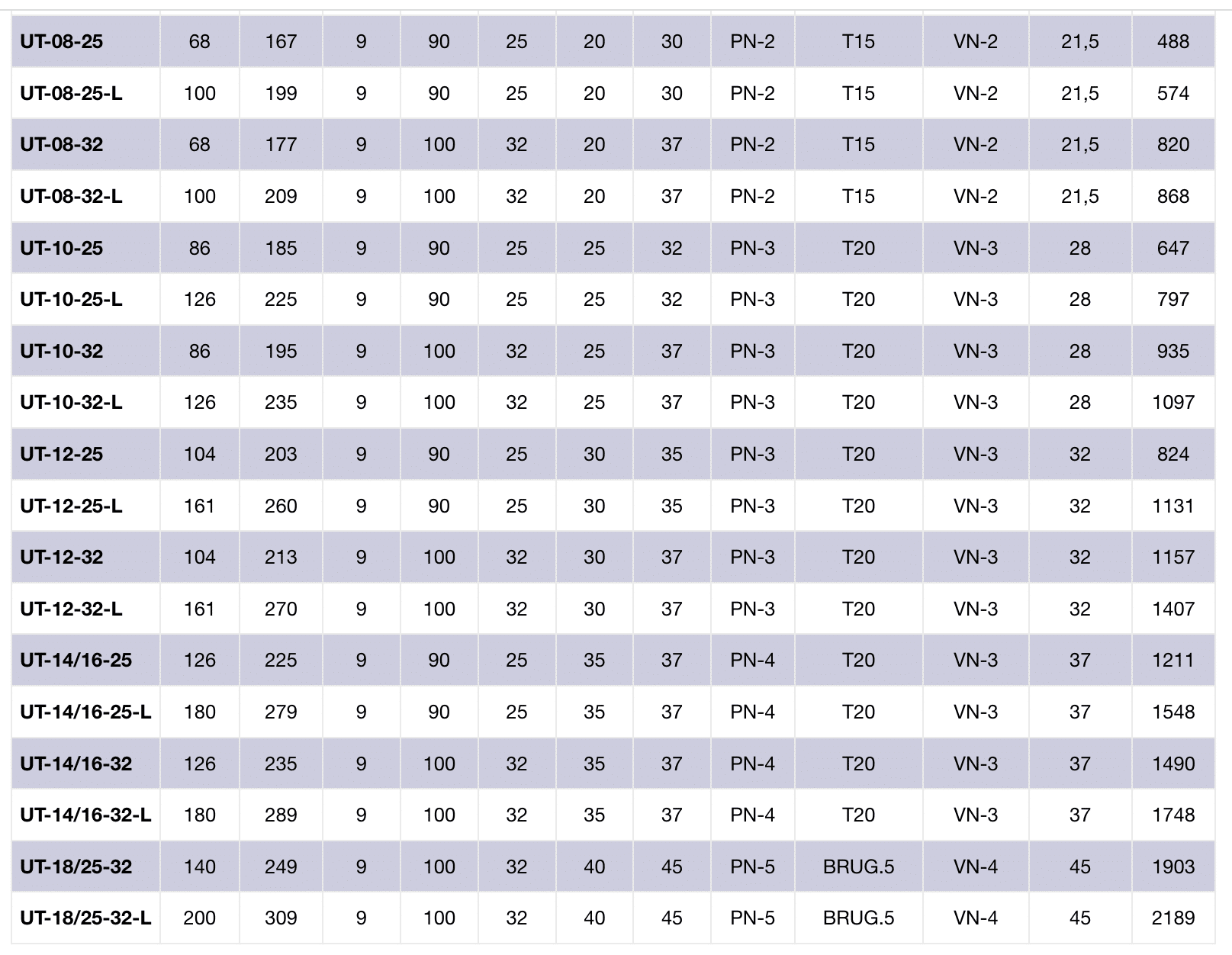

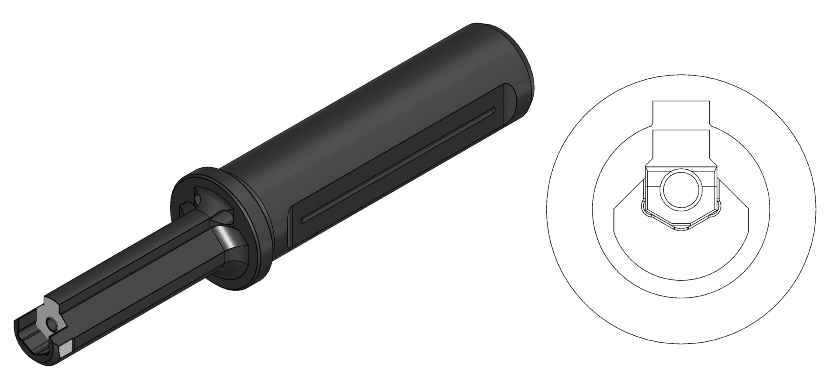

The section that houses the insert is hardened to 58/60 HRC, making it very resistant to compression and guaranteeing the tool a long service life. Most REV internal tools (shown in the table) feature 3.5 mm holes for the forced supply of coolant which, in addition to lubricating and cooling the insert, are used to extract the chips, produced through broaching or slotting, out of the blind hole. Internal tools are available in two socket diameters (diameters 25 and 32). Two tool lines are available for each socket diameter: standard and long (identified by the suffix ”L” in the code). The REV Broaching Tool differs from similar tools currently on the market by its patented eccentric bushing that completely eliminates symmetry errors. This bushing was provided so that any lathe without a Y-axis can perform machining in perfect alignment with the workpiece.

* There are 4mm holes for forced coolant adduction.